Our History

Transfer Tools was founded in 1956 by Bob and Peggy Patterson. Bob was a brilliant design engineer and Peggy was a very good organiser.

Between them they bought some old redundant buildings left over from the Airfield in Great Gransden and started designing and building special purpose machine tools.

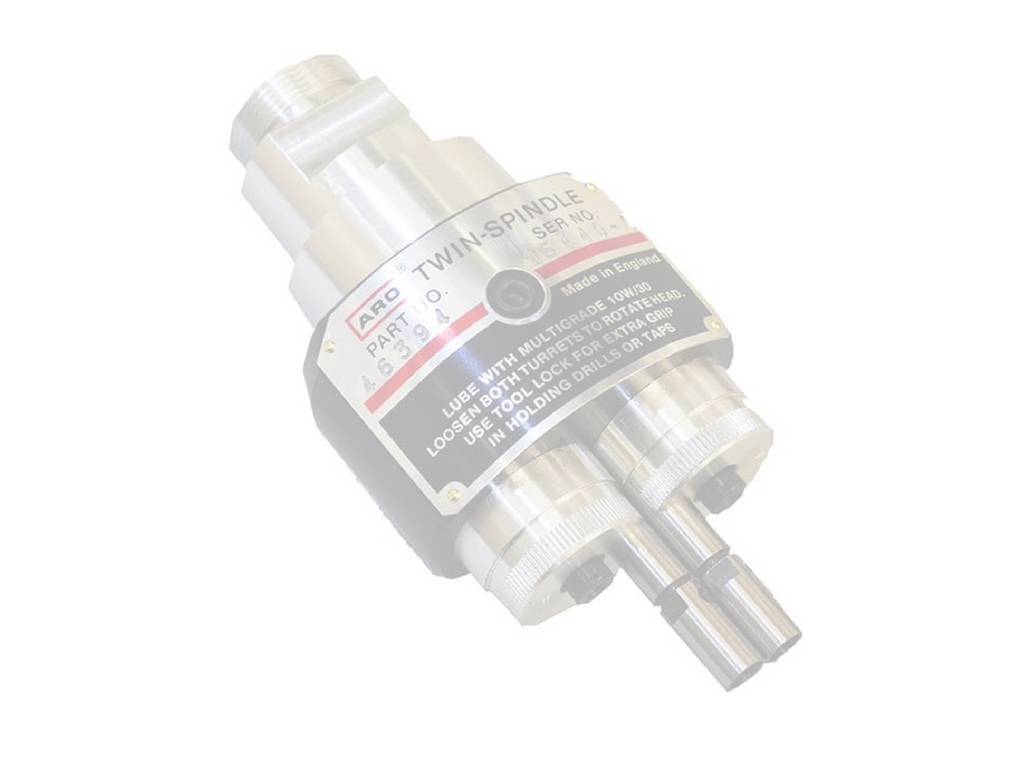

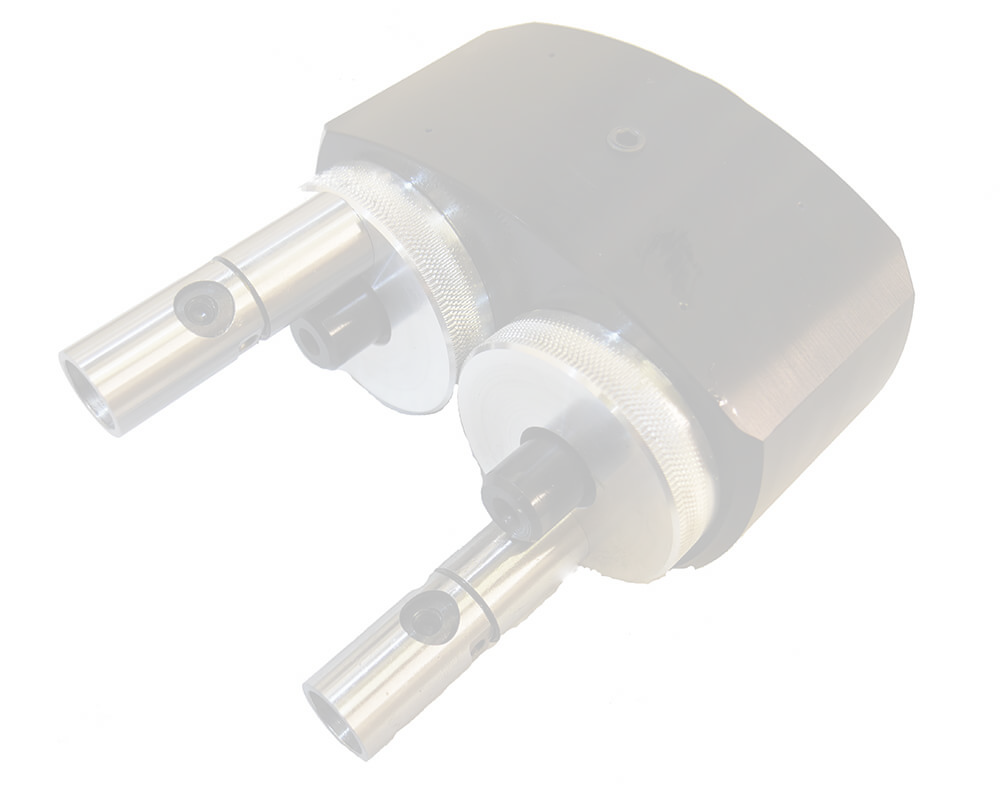

In 1960 Bob designed a very successful multi spindle drilling and tapping head that could be adjusted to suit different hole centres and so Gy Roll was born as the name was more suited to the gyroscopic rollers used in Bob’s design.

Over the years they gradually developed the site and erected a new factory and office block. Peggy created and landscaped the gardens around the small lake besides the entrance gate whilst also running the factory on a day to day basis. Bob meanwhile spent most days at the drawing board designing . The sales gradually built up with the big market being America. Gy Roll opened a second factory in Canada but it was soon decided that working through agents would be a better solution and so several Agents were appointed and Bob who had been commuting and separated from Peggy for long periods moved back home to the UK.

The Company has been streamlined and now many new CNC machines manufacture multi spindle heads to Bob’s original designs for both the European and export markets.

60 years and still going strong.